The global construction industry, a sector traditionally defined by its reliance on centuries-old manual labor, standardized forms, and slow, sequential assembly processes, is currently navigating a profound and irreversible technological revolution. This reliance on conventional methods often results in immense material waste, high labor costs, and significant limitations on achievable architectural complexity and customization.

The necessity for speed, sustainability, and unprecedented design freedom in modern architecture has outpaced the capabilities of traditional building techniques entirely. 3D Printing Technology, or Additive Manufacturing, has decisively emerged as the indispensable, specialized solution to this challenge.

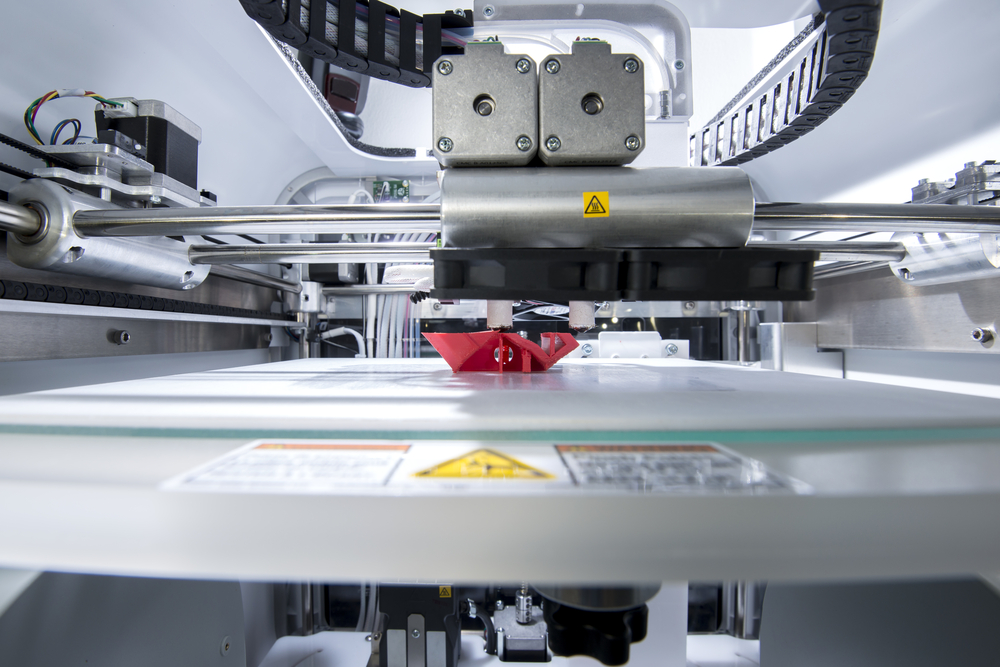

This crucial discipline involves meticulously fabricating complex, high-precision components, including entire building facades, layer by layer, directly from digital models. This process is far more than an efficiency gain. It is a fundamental transformation of material use, structural capacity, and geometric freedom in building design.

Understanding the core mechanisms, the strategic advantages for architectural customization, and the profound economic implications of this construction technology is absolutely non-negotiable. This knowledge is the key to securing material efficiency, accelerating time-to-completion, and realizing previously impossible, complex architectural visions.

The Paradigm Shift to Additive Construction

The core rationale for adopting 3D Printing in construction is the strategic imperative to overcome the limitations of subtractive manufacturing. Traditional building involves cutting, carving, and assembling standardized materials, which generates massive amounts of costly waste. Additive manufacturing, conversely, builds objects layer by layer, depositing material only where it is functionally needed. This fundamental shift minimizes waste and maximizes material efficiency dramatically.

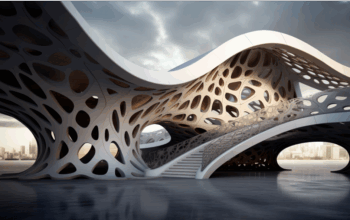

The most visible application is the direct fabrication of complex building facades and structural components. Traditional methods struggle with non-standard, organic, or intricate geometric forms. 3D printing allows architects to design and instantly fabricate highly customized, complex facade panels that optimize thermal performance and aesthetic expression. This unlocks unprecedented architectural freedom.

This technology provides immense strategic advantages in cost and time efficiency. Automated, robotic printing systems can operate continuously, 24 hours a day, with minimal human labor intervention. This significantly accelerates the construction timeline. The reduction in skilled manual labor costs translates directly into superior project margins.

The 3D printing process transforms the logistics of the construction site. Instead of complex assemblies of disparate components, the printer rapidly fabricates large, consolidated sections of the structure on-site or in an adjacent factory. This simplifies material handling and minimizes transportation logistics. This controlled environment improves final quality.

Architectural Applications of 3D Printing

The use of 3D Printing is fundamentally transforming the design and construction of the building’s external shell. Building facades are now being treated as complex, functional, and aesthetically expressive components that can be customized entirely to the project’s unique requirements. Additive manufacturing enables unprecedented geometric complexity.

A. Customized Facade Panels

Customized Facade Panels are the primary application of 3D printing. Architects can design intricate, unique textures, complex organic shapes, or sophisticated lattice patterns that would be prohibitively expensive or physically impossible to create using traditional formwork and pouring methods. The printer executes this high-precision complexity automatically. This capability provides maximum aesthetic freedom.

B. Structural Component Fabrication

3D printing is rapidly moving into the fabrication of structural components. This involves printing large, integrated wall sections, complex nodal joints for unusual structural systems, or entire low-rise building cores directly on-site. The ability to print integrated wall systems that include built-in conduit channels, insulation pockets, and structural reinforcement drastically reduces the total number of components required for assembly. This structural consolidation enhances efficiency.

C. Advanced Material Optimization

The technology allows for advanced material optimization. 3D printing systems can utilize customized cement-based mixtures, high-performance polymers, or geomaterials (e.g., local sand and earth) as feedstock. Research focuses on creating materials that are not only strong but also optimized for insulation or reduced embodied carbon. This control over the material composition enhances sustainability.

D. Formwork and Mold Printing

3D printing is also used indirectly for creating highly complex, reusable formwork and molds. This is necessary for traditional concrete pouring when the architectural design demands highly intricate, non-standard, curved, or fluid geometric shapes. Printing the mold is significantly faster and cheaper than manually building custom wooden formwork for every pour. This reduces the time and cost associated with complex, one-off structural elements.

Strategic Benefits for Construction Efficiency

The strategic adoption of Additive Manufacturing offers profound, quantifiable benefits that impact construction speed, cost structure, and environmental sustainability. These benefits directly address the core operational failures of traditional subtractive construction. Efficiency is the new metric of quality.

E. Waste Reduction

The most significant environmental and economic benefit is Waste Reduction. By building components layer by layer, 3D printing utilizes only the necessary material volume. This precision minimizes the need for cutting, trimming, and processing large raw materials. Construction waste sent to landfills is drastically reduced. This accuracy is key to a sustainable construction model.

F. Accelerated Time-to-Completion

Automated, continuous printing systems operate with minimal downtime and without mandatory rest periods. This significantly accelerates the time-to-completion for the entire project. Rapid deployment minimizes the risk associated with weather delays and supply chain instability. Faster construction translates directly into earlier revenue generation for the developer.

G. Labor Cost Optimization

3D printing dramatically reduces the reliance on highly skilled, manual labor for repetitive tasks like bricklaying, pouring formwork, or intricate assembly. Robotic systems require only a small team of technicians to monitor the automated process. This shift significantly reduces the high cost of skilled construction labor. Labor cost optimization is a major financial incentive.

H. Safety Improvement

The automation of high-risk, dangerous, and physically strenuous tasks improves construction site safety significantly. Printing systems eliminate the need for human workers to operate at extreme heights, in unstable trenches, or in hazardous environments. This minimization of human exposure to danger reduces the incidence of severe workplace injuries. Safety is automated by design.

Integration and Future Trajectory

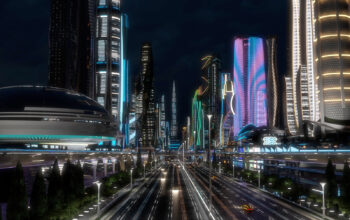

The future trajectory of 3D Printing in Architecture is defined by deeper integration with advanced data analytics and the move toward highly automated, modular construction systems. The technology will fundamentally reshape urban fabrication methods. Integration is the next challenge.

I. BIM Integration and Code Compliance

Building Information Modeling (BIM) software provides the precise digital models that directly feed instructions to the 3D printer. Advanced systems integrate AI with BIM to check design models against local building codes and regulatory compliance instantly. This automated code-checking minimizes legal errors. It ensures that the printed structure adheres strictly to all safety and dimensional requirements.

J. Modular and Off-Site Fabrication

The technology is essential for modular and off-site fabrication. Large building components or even entire residential modules are printed in controlled factory environments. This controlled process enhances quality and reduces weather-related delays. The modules are then transported to the final site for rapid, final assembly. This strategy accelerates the construction pipeline.

K. Autonomous Assembly Robotics

The next evolution involves combining 3D printing with autonomous assembly robotics. Specialized robots will work in coordination to print components and then assemble them on-site. This completely automated construction site will further reduce labor requirements. This enhances construction speed exponentially.

L. Customized Housing and On-Demand Printing

3D printing holds the powerful potential to revolutionize customized housing and disaster relief. Houses can be designed and printed rapidly in response to specific, individual needs or immediate humanitarian crises. This on-demand fabrication provides a scalable, cost-effective solution for low-income housing and immediate shelter provision. The technology enables rapid humanitarian response.

Conclusion

3D Printing is the indispensable technology revolutionizing architectural construction, speed, and efficiency.

The core mechanism utilizes an additive, layer-by-layer fabrication process that fundamentally minimizes costly material waste dramatically.

The technology provides necessary design freedom, enabling the rapid fabrication of complex, high-precision, non-standard facade panels.

Structural components, including integrated walls and building cores, are printed on-site or off-site, drastically accelerating the entire construction timeline.

Automation of the building process significantly reduces reliance on high-cost manual labor, transforming overall project cost structures.

Rigorous integration with BIM software is mandatory for feeding precise digital models to the printer and ensuring strict code compliance.

The strategic commitment to this technology yields immense environmental benefit by minimizing construction waste and optimizing material use.

Safety is enhanced by automating high-risk manual tasks, physically removing human workers from hazardous construction environments.

Future adoption relies on modular fabrication, where entire building components are printed in a factory and rapidly assembled on the final site.

Mastering this technology is the ultimate key to achieving operational efficiency, securing material optimization, and maximizing final project profitability.

3D printing stands as the final, authoritative guarantor of design freedom, speed, and sustainability in the global built environment.

This specialized discipline transforms the rigid, traditional world of construction into an agile, customizable, and automated industry.